From Hobby to Harvest: How 3D Printing is Revolutionizing Modern Coffee

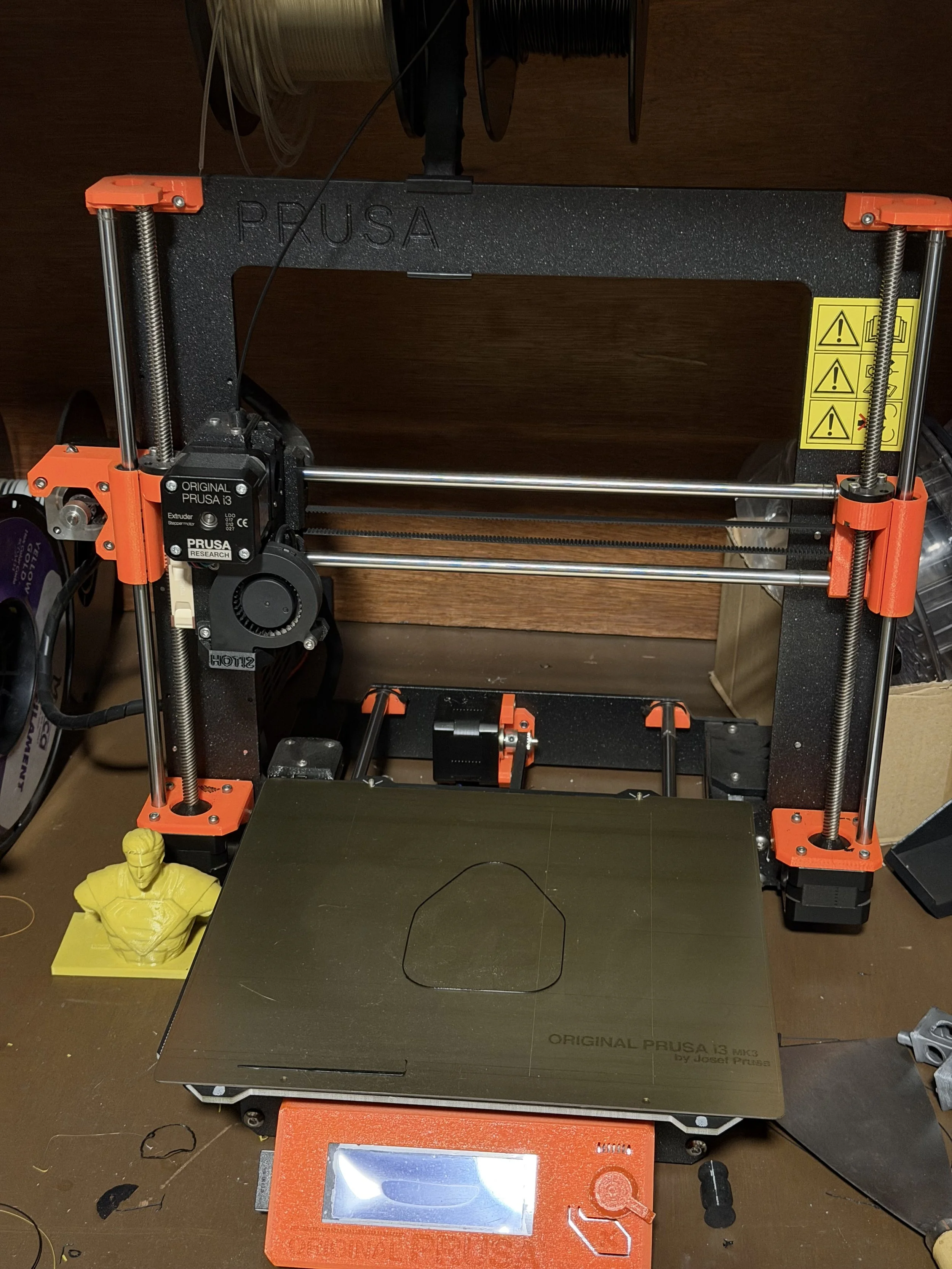

In 2016, I found myself sitting in the middle of my kitchen floor surrounded by wires, bolts, aluminum frames, and a set of instructions that felt more like a puzzle than a manual. I had just bought my first 3D printer.

Back then, these machines didn’t arrive ready to go. You built them yourself. You calibrated them through trial and error. You learned patience very quickly. My first prints looked like melted spaghetti. But somewhere between tightening screws and watching that first successful layer stick to the bed, something clicked.

This wasn’t just a hobby.

It was a new way of thinking.

At the time, I was printing small novelty items—figurines, bag clips, simple household tools. But as someone deeply rooted in coffee, my mind naturally began to wander. What if this technology could solve real problems in our industry? What if it could empower farmers, roasters, baristas, and technicians to improve their own systems instead of waiting for someone else to fix them?

Over the past two decades, I’ve worked across the entire coffee value chain—from origin communities in Benguet, Cavite, and Laguna to competition stages and café floors. And one truth remains constant: in coffee, small details matter. Sometimes the smallest component determines whether an operation runs smoothly or comes to a complete stop.

A broken depulper during harvest can mean lost income for a farmer. A cracked grinder fork in a busy café can disrupt workflow and consistency. A missing knob or bracket in a roastery can delay production. These aren’t dramatic failures. They’re small, everyday breakdowns. But in coffee, timing is everything.

Traditionally, when something breaks, we order a replacement. We wait. We adjust.

But what if we didn’t have to wait?

3D printing is quietly transforming that equation. Today, coffee professionals can design and print replacement parts, custom dosing tools, workflow organizers, sensor mounts for drying beds, irrigation fittings, and ergonomic enhancements for daily operations. Instead of adapting to tools designed for generic global markets, we can begin adapting tools specifically for our own environments.

This is where modern coffee begins to evolve.

What excites me most isn’t just the technology—it’s the rise of makers within our industry. Passionate individuals who look at an existing grinder, scale, or brewing device and see potential for improvement.

One example is Meherdad of @Fused Visions, a maker based in Germany who creates beautifully engineered add-on modifications for grinders, drippers, and scales. His designs enhance alignment, improve dosing consistency, and refine workflow. He doesn’t replace the original machine. He improves it—thoughtfully, precisely, respectfully.

That spirit represents something powerful.

Innovation doesn’t always have to come from large manufacturers. Sometimes it comes from an enthusiast who wants cleaner distribution. Sometimes from a barista who wants better alignment. Sometimes from a farmer who understands exactly how fermentation behaves in their microclimate.

3D printing gives these ideas physical form.

At some point, my curiosity moved beyond experimentation and into creation.

I began asking myself a simple question: What if we could design tools specifically for how we actually brew and experience coffee—rather than constantly adapting ourselves to tools that were never built for our workflow?

Back in 2023, that question eventually led to what I now call the Better Vessel—an invention I introduced at the 2025 World Barista Championship, which helped us earn the Highest scoring espresso during the live ranking.

The idea came from a very specific challenge: crema.

As beautiful as crema looks, it can mask clarity and distort flavor perception in espresso. In competition, where precision matters at the highest level, I wanted more control over how flavor was presented in the cup. I didn’t want to remove crema manually or disrupt the flow of service. I wanted a system that would do it intentionally, consistently, and efficiently.

So I designed one.

The Better Vessel works using gravity and precise physics. Its geometry allows separation to happen naturally through controlled flow and layering. No aggressive agitation. No complicated mechanisms. Just thoughtful design that guides liquid behavior exactly where it needs to go.

At the same time, I was deeply conscious of workflow. In competition—and even more so in a busy café—every movement matters. The vessel had to feel intuitive in the hand. It had to integrate seamlessly into the brewing sequence. It had to enhance efficiency, not slow it down.

Instead of waiting for a manufacturer to interpret the idea, I prototyped it myself.

Through 3D printing, I was able to test angles, wall thickness, geometry, internal contours, and volume capacity. I would print, brew, adjust, and reprint—often overnight. What traditionally would have taken years of industrial tooling happened in days of hands-on iteration.

The Better Vessel wasn’t designed in a boardroom. It was shaped through brewing, tasting, refining. Guided by physics, but grounded in sensory experience.

And that’s the power of modern coffee innovation.

3D printing allows ideas to move at the speed of thought. It allows coffee professionals to experiment without waiting for permission. It allows us to transform insight into physical reality.

If a barista like me can design a better vessel, a farmer can design a better fermentation valve. If a coffee enthusiast can refine a pour-over tool, a roaster can improve airflow components. If an entrepreneur in Germany can enhance grinder functionality with precision add-ons, a young innovator in Benguet can redesign a drying bed to adodot to mountain humidity.

The Better Vessel is not just an invention.

It’s proof that we don’t have to wait for innovation to arrive from somewhere else.

We can build it ourselves.

It shifts us from being passive users of equipment to active participants in its evolution. It encourages experimentation. It rewards curiosity. It invites collaboration.

Imagine a shared maker space in a coffee-growing community where farmers can print replacement components during harvest. Imagine a roastery with a small design corner where staff prototype workflow improvements. Imagine baristas who understand not only extraction theory, but also mechanical design principles.

This isn’t about replacing tradition. It’s about strengthening it.

Coffee has always been a blend of craft and science. Fermentation meets precision. Sensory intuition meets data. Now we’re adding another layer—accessible innovation.

Sustainability in modern coffee isn’t only about environmental practices or certifications. It’s also about resilience. About reducing downtime. About empowering communities to solve their own problems. When farmers can repair instead of replace, when cafés can improve instead of discard, when entrepreneurs can refine instead of reinvent, we create a stronger ecosystem.

Every layer of filament printed is a small declaration of independence.

When I look back at that printer I assembled in 2016, I realize it was never just about technology. It was about possibility. About asking better questions. About believing that even small tools can create a big impact.

Modern coffee isn’t defined only by better brewing techniques or more advanced roasting software. It’s defined by our willingness to innovate together. Farmers, makers, roasters, baristas, engineers, and entrepreneurs shaping the future collaboratively.

From hobby to harvest, from kitchen floor experiments to the World Barista Championship stage, 3D printing has shown me something important: the future of coffee belongs to those who are willing to build it.

Not just grow it.

Not just brew it.

But design it. Improve it. Reinvent it.

When we empower people across the value chain to create solutions with their own hands, we grow more than better coffee.

We grow ownership.

We grow resilience.

We grow a modern coffee culture rooted in creativity and shared progress.

And that is how we build a truly beautiful coffee future.

— Michael Harris Conlin